Nom Diameters up to 2500 mm

Pressure Range up to 30 Bar

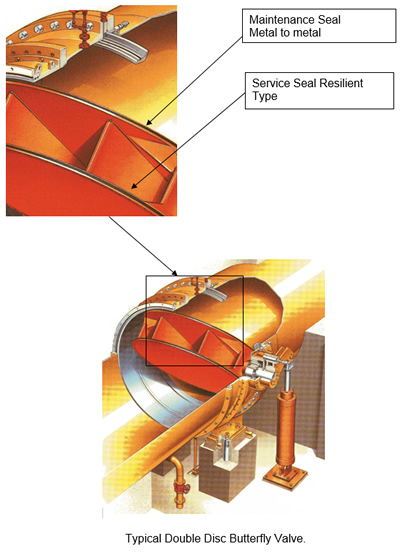

The Double Disc design offers a true double sealing feature. The upstream maintenance seal and downstream service seal have an independent sealing arrangement fitted on the corresponding disc face. The Double Disc offers a similar function to a ‘Double Block and Bleed‘ feature with the two sets of seals and inter space between the seals connected to drain.

The separate maintenance seal allows the service seal to be repaired or replaced without the need to drain upstream pipe/penstock.

The service seal is a resilient rubber seal with the maintenance seal a metal to metal type.

The maintenance seal is not in contact with it's seat during normal operation thus minimising its wear during normal operation and reduced seal friction torque.

Replacement of the maintenance seal replacement will require dewatering the upstream pipeline.

Double Disc sealing offers safe isolation to allow maintenance personnel to work downstream of valve with double isolation points to meet stringent safety requirements and is an alternative for low and medium head Spherical Valve due to its compact size, sealing feature and price. The valve can be sized based on optimum head loss.

Applications are,

- Penstock Protection Valve

- Turbine Inlet Valve

- Guard Valve

- Guard Valve for Howell Bunger (Fixed Cone Valve)

- CW Pump Discharge

Fail safe operation can be provided via counter weight closure.