Background

eTec were awarded a contract to design and supply 2 off 68” Spherical Valves to replace existing 1950’s Boving Valves for a hydro power station in Scotland. The existing valves were operated by a double acting penstock water operated hydraulic cylinder all within a restricted valve pit.

Design Requirements

The customer required the new valves to have, counter weight closure under fail safe mode, double sealing capability, mechanical locking of moving parts, increased maintenance space and to be designed to fit within confines of the existing valve pit with no civil works. The existing foundation support structure was also to be reused and guarding of moving parts provided.

The Solution

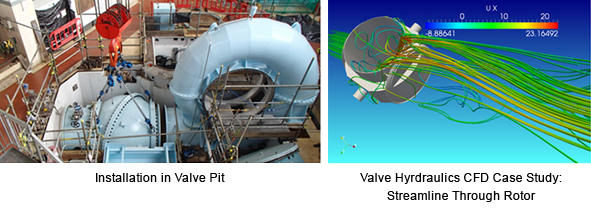

The valve pit was surveyed to best utilise the space available, a Spherical type design was chosen to provide the flow characteristics required. The valve body was designed with a diagonally split to optimise the space with trunnions internally bolted to the rotor to reduce the projection outside the body shell and the counter weight shaped to maximise the available space. To meet the specification the valve was designed with a drop tight nitrile service seal and a sliding metal to metal maintenance seal. The maintenance seal being provided with mechanical locks, indicators and limit switches with operation by either penstock water or an auxiliary pump. eTec worked closely with the customer throughout the contract to ensure programme, risk and safety matters were considered and interfaces were taken care of. An Inlet Pipe and Dismantling Joint completed the installation. Both valves were delivered on time twelve months apart and installed without issues.

A CFD study was carried out to validate the valve torques and operator sizing.