Background

eTec were awarded a contract to supply 4 off 60”Diameter (1525 mm) 35 bar design pressure Spherical valves to replace existing 1950’s English Electric Cylindrical Balanced Valves for a hydro power station in Scotland. The existing valves were internal piston operated by penstock water pressure with the valve Body partially embedded in concrete. Customer’s requirement was to improve the head loss across the valve, move to high pressure oil operation and have a design that met transient conditions, PED and locking / indicator arrangements.

Design Requirements

The new valves were required to meet 35 bar design pressure tested to 52.5 bar and to close under fail safe mode. The design had to fit within confines of the limited valve pit . A new Dismantling Joint was required to allow installation and access to service seal.

The Solution

The new valves were designed with a Double acting servomotor incorporating a locking mechanism at both closed and open positions. A metal to metal seated sliding service seal was used to close off the water flow with the rotor was moved to the closed position and act as an internal bypass for opening the valve. This removed the requirement for a separate bypass line significantly reducing the installation space. A new Dismantling Joint and tapered Inlet Pipe designed to meet current specifications was supplied. The hydraulic cylinder mounted on valve body allowed for the valve to be supplied fully assembled and installed following works testing. The supplied TIV offered improved hydraulic performance and station protection against a turbine trip scenario.

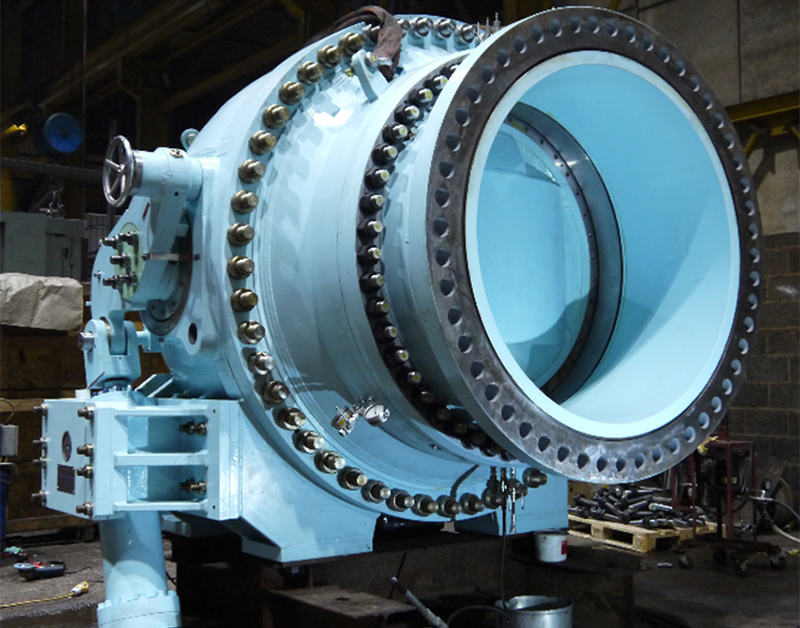

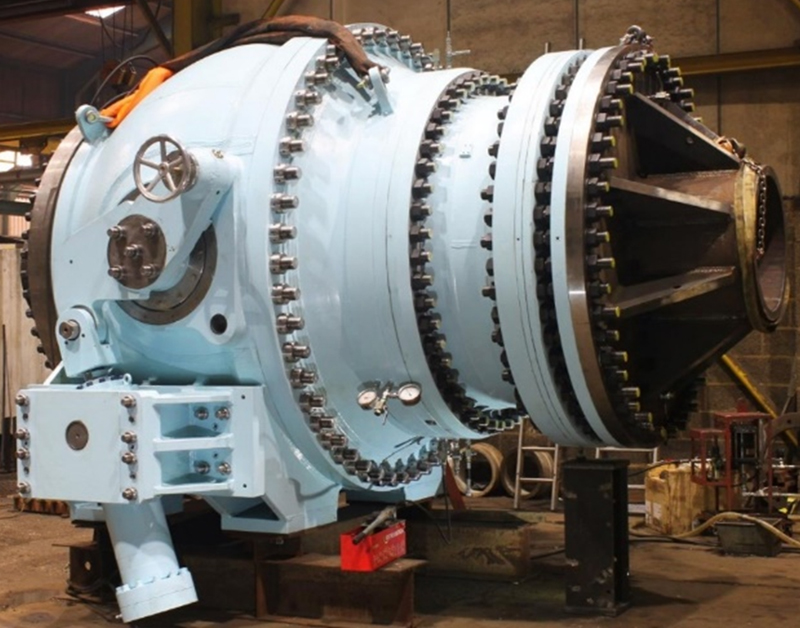

Valve Assembly

Assembly during Works Pressure Testing