Background

The Hydro Power station penstock constructed in mid-1930’s from individual spools required replacing. The penstock has numerous expansion joints formed with socked joints to allow for movement of the pipe due to temperature changes.

Current access to penstock pipe for inspection requires removable of the Dismantling Joints at difficult access of both the low and high pressure penstock.

Design Requirements

- The Dismantling joints were required to provide man access point.

- Provide a removable length of pipe for plant and equipment to carry out internal examination and maintenance.

- Act as an Expansion Joint for free axial thermal movement of the pipeline.

- Provide a pressure tight joint.

The Solution

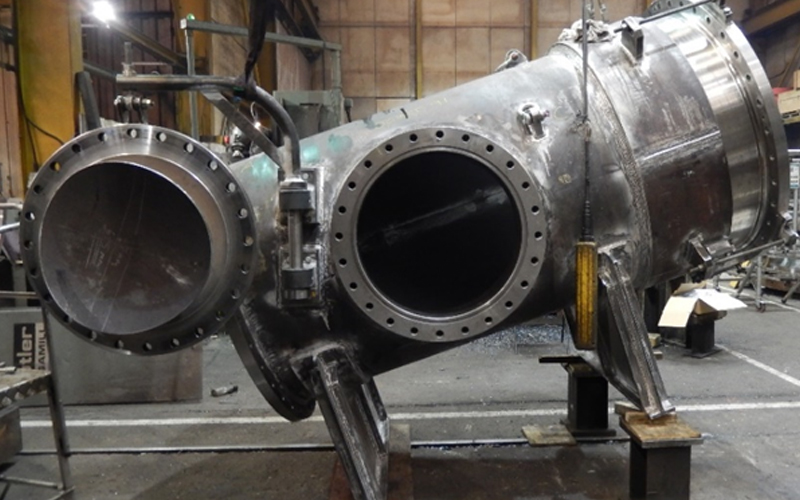

The new Dismantling Joints were designed, with a set of three ‘D’ Seals in contact with a section of Stainless Steel sliding pipe providing an installation ‘gap’ whilst also allowing for penstock expansion. The seal design requires no adjustment or tightening to achieve sealing.

An access manhole with a cover mounted on a Davit Arm was provided, designed to avoid site lifting whilst also considering the installed penstock pipe inclination angle.

The assembly was provided with a saddle support suitable for a low friction sliding bearing pad.

A makeup pipe with a flange was designed for site welding to the penstock to connect to the Dismantling Joint and provide the removal facility.

The Dismantling Joint was workshop assembled and seals tested to 1.1 times max operation pressure to prove the seal integrity.

Supplied with tie-rods and pipe lugs for jacking purpose to assist installation and a facility to lock the Davit Arm in the open position.

Dismantling Joints were designed and supplied for the low and high pressure sections of the penstock.

28 bar Dismantling Joint

with Manhole access

16 bar Dismantling Joint

with Manhole access

16 bar Dismantling Joint

during Works Assembly